1.It is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

² power:380V50Hz² Input power:2.2KW² Rated oil pump pressure:20Mpa² nominal pressure:40KN² Punching stroke:30MM² capacity of tank:30L² Oil pump dimension:6寸² Overall dimension:1000*1100*1600mm(L*W*H)weight:650Kg

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

LMB-SZ-120ZIt is suitable for angle-code punching and riveting connection of aluminum doors and windows curtain wall, with heavy structure and stable performance.

Contact Now

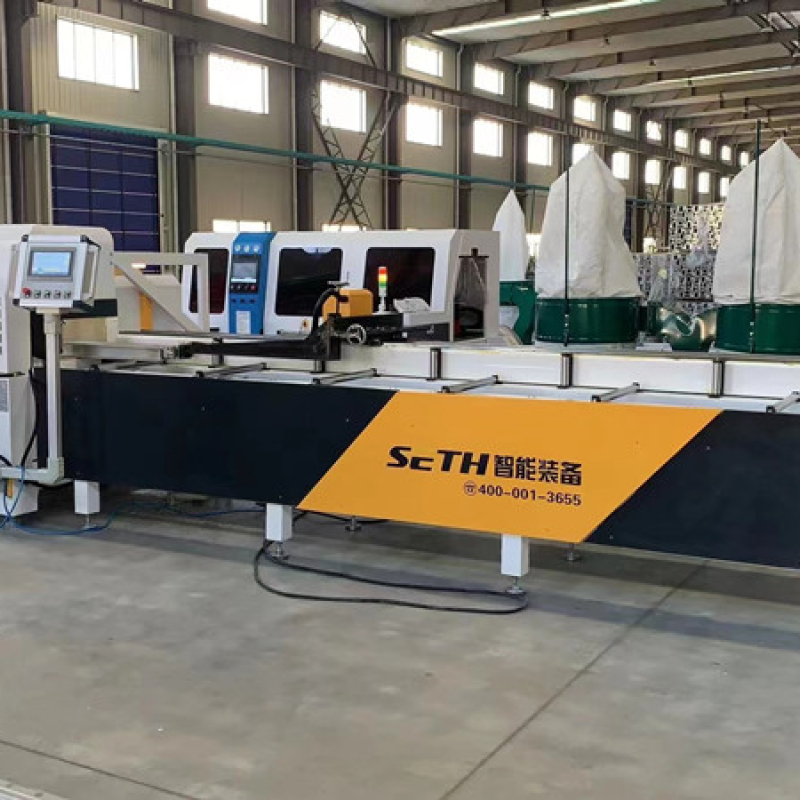

● Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

LXD-200AIt's miles appropriate for forming various give up grooves of aluminum profiles.Excessive-precision spindle ensures machining accuracy.Computerized feeding, low exertions intensity.The workbench can be adjusted up and down, making it handy to regulate the knife.Linear bearing ok inematic pair is used for slicing device feeding, which makes the running overall performance solid.Power supply380V/50HzRating power2.2kWMilling cutter rotary speed2800r/minAir consumption80L/minProfile height30~120mmProfile width20~120mmOverall dimension8500×740×1280mmWeightAbout 200kg

Contact Now

● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import&n

Contact Now

LJZ2-CNC-550*4300High-quality cemented carbide saw blades for aluminum materials areselected, with high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The saw blade automatically swings at an angle of 45° a

Contact Now

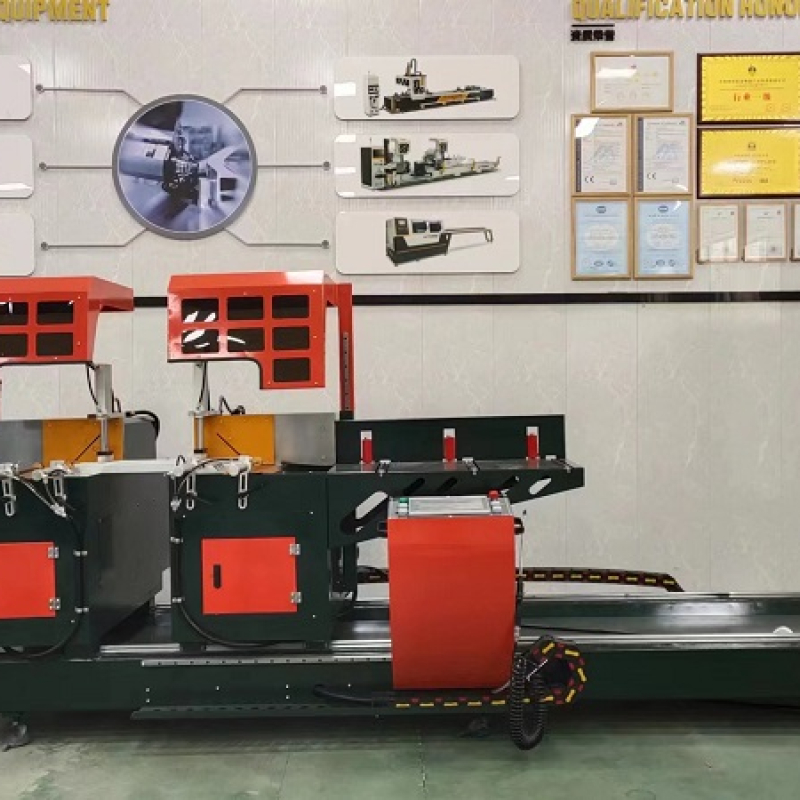

1. The machine adopts electric control technology, which can complete the positioning cutting and cutting of different sizes of profiles.2. Right head feed with high screw ball screw movement, high precision, good stability3. Imported hard alloy saw blade, high cutting quality, long service life, the selection of high-quality aluminum special hard alloy saw blade, high wire speed, moving and feeding device using linear bearing system, to ensure the accuracy of machine operation and cutting, stable performance.4.

Contact Now

Features of equipment:Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.● Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.● High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated gas-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.● Supports multiple data import modes:Internet, LAN, U disk, Bluetooth, manual input, etc.

Contact Now

LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

LJZ2-CNS-450*3700AHigh precision spindle makes the saw blade rotate stably.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).When the machine works, the saw blades with two saw heads can cut at the same time or separately.With the saw blade from back to front, the sawing profile is safer and more reliable, and the sawing height and width are very large.The saw blade can automatically swing to the

Contact Now

LJDX-BP-250*5It is suitable for milling the end face of aluminum profile, so as to meet the matching between center stile and frame material.

Contact Now

LJZ2Z-CNC-550*4300Using cemented carbide saw blade, the outer diameter can reach 550,the linear speed is high, and the machining precision is high.High transmission precision, accurate positioning and stable operation.High precision spindle motor makes the saw blade rotate stably.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.When the machine works, the saw blades with two saw heads can cut at the same time or separately.The machine head is fixed at an angle of 45° to ensure stable precision in long-te

Contact Now

Mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also used for cutting and blanking PVC and wood profiles.The machine adopts numerical control technology, and can complete automatic positioning, cutting and blanking of profiles with different specifications and sizes.High-quality carbide saw blades for aluminum materials are selected, with an outer diameter of 500, high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate posit

Contact Now

It is mainly used for cutting industrial aluminum profiles, broken bridge aluminum doors and windows, curtain wall materials, and also for cutting PVC and wood profiles.

Contact Now

Power supply380V/50HzSaw head motor2×3.0kW 2840r/minWorking pressure0.6~0.8MPaAir supply60L/minCutting length410~4300mmCutting widthMax. 210mmCutting heightMax. 320mmMax. cutting slope45°210×280mm 90°210×320mmCutting angle90°, 45°Feeding speed0~3m/minSaw blade specificationФ600×4.4×Ф30 Z=144 (saw blade 500/550/600mm)Overall dimension7800×1500×2040mmWeight2600kg

Contact Now

LJZ2-CNS-500*4300The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The machine head can rotate automatically, position and clamp in two directions, and can work independently with a single machine head.Automatic opening and closing of protective cover makes operation safer.The saw blade automatically swings at an angle of 45° and 90° , and

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, PVC profiles, aluminum doors and Windows, curtain wall materials.☆ Operation without skilled workers, solve the factory recruitment difficulties, label printing function, error prevention function: profile error beyond the range of no cutting.☆ High-precision, integrated casting workbench, integrated spindle directly connected motor, integrated air-liquid damping cylinder, T1, T2 heads are located on the integrated guide rail.☆ Supports multiple data import modes:Internet, LAN, U di

Contact Now

LJZ2-CNC-600*4300High-quality cemented carbide saw blades for aluminum materials areselected, with high linear speed and high machining accuracy.Numerical control transmission adopts high standard gear rack, with high transmission precision, accurate positioning and stable operation.The high-precision spindle makes the saw blade rotate stably and effectively improves the surface quality of the workpiece.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.The saw blade automatically swings at an angle of 45° and 90°

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

LJZ2-CNC-600*4300High-pleasant cemented carbide noticed blades for aluminum substances areselected, with excessive linear pace and excessive machining accuracy.Numerical manipulate transmission adopts excessive popular gear rack, with excessive transmission precision, correct positioning and strong operation.The excessive-precision spindle makes the noticed blade rotate stably and successfully improves the floor pleasant of the workpiece.Gas-liquid damping cylinder realizes uniform feed pace law and strong movement.Adopt micro spray cooling device.The saw blade automatically swings

Contact Now

Aluminum CNC Double Head Cutting SawCNC Cutting Saw Machine Model:LJZ2Z-CNC-550*3500Our aluminum CNC double head cutting saw machines mainly used for cutting and blanking systemdoor and window profiles at 45° angle,and can also be used for cutting and blanking plastic profiles.Adopt square guide rail,with high precision of repeated positioning.This model cutting saw machine adopts numerical control technology,and can complete automaticpositioning,cutting and blanking of profiles with different specifications and sizes.Using cemented carbide saw blade,the outer diameter can reach 550

Contact Now

Power Supply380V/50HzSaw Head Motor2*3.0km 2840r/MinWorking Pressure0.6~0.8MPaAir Supply60L/MinCutting Length410~4300Cutting WidthMax.210mmCutting HeightMax.320mmMax.Cutting Slop45° 135X220mmCutting Angle90° 45°Feeding Speed0-3m/minSaw Blade SpecificationΦ600X4.4XΦ30 Z=144Overall Dimension5800X1900X1700mmWeight2000kg

Contact Now